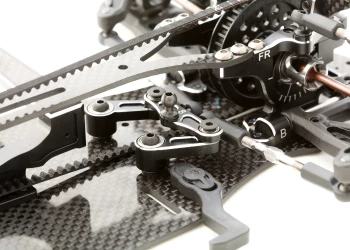

Lightweight materials reducing weight of suspension systems

Add bookmarkReducing weight has become one of the hottest topics in the automotive manufacturing sector, driven largely by the need to reduce emissions to suit ever-decreasing targets.

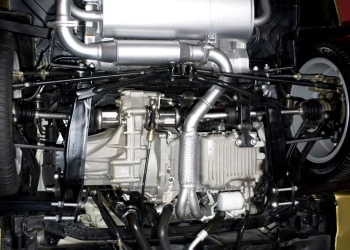

Body and drivetrain have come under intense scrutiny in the endeavour to save weight and an array of innovative concepts have been developed over recent years to achieve it.

Some of the most fascinating advances have been seen in the use of composite vehicles to replace parts and components traditionally manufactured from steel. While carbon-fiber reinforced plastics (CFRP) and glass reinforced plastics (GRP) have great potential to reduce the weight of passenger cars, any designs must be balanced against the pragmatic constraints of production vehicles.

Safety is paramount and any designs must be structurally robust enough to adhere to current and future crash safety targets. Cost of production is also a key issue, and while processes are improving considerably, there is still progress to be made in terms of cost-effective mass production. Another important issue is the rapid development of electric vehicles and 48 Volt architecture. The electrification of vehicles over the coming decades provides various opportunities for more advanced suspension systems, and again, these must be considered as part of a holistic approach to lightweighting while improving performance.

Recent years have seen plenty of development in suspension systems and the use of lightweight materials, a trend which has continued throughout 2017.

Lightweighting trends and innovations

Back in 2014 Audi introduced GFRP suspension springs in an effort to reduce weight, and the German automaker has unveiled a range of innovations since. The lightweight springs, constructed from a glass-fiber reinforced polymer composite enabled a weight saving of 2.5 kg per spring, and a 40% reduction compared with steel springs.

The springs are constructed of long glass fibers twisted together and impregnated with epoxy resin. This structure is then wrapped with more glass fibers at counter-poised 45 degree angles. As well as providing comparable strength to steel springs, the GFRP springs are unaffected by corrosion or chemicals and use less energy in production.

A similar advance was made by Volvo in 2015 when it introduced new leaf springs for the XC90, manufactured from a glass-fiber reinforced composite material. Behind the leaf springs were automotive suppliers Henkel and Benteler-SGL. Henkel (well-known for its adhesive technology), also produces solutions for automotive structural components using high pressure resin transfer molding (HP-RTM).

The company’s Loctite MAX 2 two-component polyurethane composite matrix resin system enabled composites specialist Benteler-SGL to produce the RTM glass-fiber reinforced springs for Volvo. Used in place of traditional steel springs, these new composite components reduce weight by 4.5 kg. One key advantage in terms of production is that Henkel’s Loctite MAX 2 has a very low initial viscosity. This enables fast injection into the mold and excellent penetration between glass fibers, while the quick curing time could allow demold times as little as one minute per part.

To further their collaboration with automotive OEM’s and tier 1 suppliers, Henkel has established two composite labs - one opened in 2016 in Heidelberg, Germany, and one established in 2017 in Isogo-ku, Yokohama. The labs have been created to enable automotive customers to team up with Henkel experts to develop and test composite parts and to assess the best production processes to bring concepts to market.

Engineers will be able to undertake trials at the lab in Heidelberg using high-pressure resin transfer molding (HP-RTM) equipment, including a 380 tons press and injection machine for polyurethanes and epoxy materials. Technology that Henkel is working on includes a coil spring made of composites which is 30-40% lighter and just as stable as traditional steel springs.

The problem of cost of production is neatly highlighted by a concept at the other end of the scale - Ford’s 2016 GT, unveiled at its Palo Alto research and innovation center last year. The lightweight supercar uses a range of materials such as magnesium and carbon-fiber to significantly reduce weight, and according to Ford CEO Mark Fields at the time, it represents “a whole decade of work into areas around lightweighting”. At over $ 400,000, the new GT highlights the issue of cost, but as production processes become cheaper the technology will trickle down to mass volume models.

Audi suspension concepts

Earlier in 2016 Audi debuted the all-new A4 Allroad Quattro at the Detroit Motor Show, featuring optional suspension with damper control for the first time. Sensors measure the movement of all four wheels plus lateral and longitudinal acceleration, and the damper characteristic adapts accordingly to surface conditions and driving situation.

An updated five-link suspension is used on the front axle, with Audi developers reducing weight by 5 kg compared to the previous version. In the rear a five-link construction replaces the trapezoidallink suspension previously used, with an intelligent mix of materials used to reduce the weight of axle components by 7 kg. Later this year Audi also unveiled the 2017 Q5, which also features the five-link suspension system, as well as optional adjustable air suspension.

Yet another innovation from Audi is seen in the ‘eROT’ prototype, in which electromechanical rotary dampers replace the conventional hydraulic dampers to enable a system which recuperates energy. The principle behind eROT is to use the energy lost to heat. Undulations in the road surface cause kinetic energy in the car, and conventional dampers absorb this energy. With the electromechanical system - which will rely on a 48 Volt electric architecture - the energy can be recouped. To do this a lever arm absorbs the motion of the wheel carrier. This arm transmits the force via a series of gears to an electric motor, which converts it into electricity.

As Audi develops its 48 Volt line-up, 2017 has seen a development of suspension technology in the new A8 with the Fully Active Suspension system. The electromechanical system drives each wheel individually via an electric motor linked to the 48v electrical system, adapting dynamically to the prevailing road conditions. Working in conjunction with the air-suspension fine-tuned for the A8, the electronic chassis platform (ECP) processes road surface information and controls all components of the suspension in almost real-time.

Citroën hydraulic suspension

Citroën has used a successful hydropneumatic suspension for some sixty years, but last year confirmed it would discontinue the system. In June 2016 the automaker released details of an all-new innovative hydraulic suspension as part of its Advanced Comfort program.

Where conventional suspension systems use mechanical stops, Citroën’s new system includes two progressive hydraulic cushions - one for rebound and one for compression - at the top and bottom of each suspension unit. The configuration allows the suspension to act in one of two ways depending on road conditions:

In instances of slight rebound and compression the springs and shock absorbers work together to control vertical movement without the need for the cushions. However, the new cushions provide the vehicle with greater freedom to deliver what Citroën calls a ‘magic carpet’ ride.

When more significant rebound and compression forces are in play, the springs and shock absorbers work together with the hydraulic cushions at the ends of the suspension travel. The cushions gradually slow the movement rather than having abrupt stops at the extremes of compression and rebound. Unlike a mechanical stop, which absorbs and partially returns energy, the hydraulic cushions absorb and dissipate energy.

Citroen has continued with the implementation of this technology throughout 2017, and the new C4 Cactus - available from January 2018 - will be the first model in Europe to feature the Progressive Hydraulic Cushion (PHC) suspension system.

Lightweight composites to reduce weight

Although drive comfort and regeneration are important topics in suspension systems, the main motivator for using different materials is to reduce the overall weight of the vehicle without affecting performance. To this end one of the industry’s most prominent component suppliers, ZF, is continually developing new designs.

One study carried out by ZF demonstrates the use of GRP to reduce the number of components in a typical axle. Where a conventional chassis features a complex control arm and spring concept, the ZF engineers have used a single component - a wheel-guiding transverse spring - to assume the task of optimal roadholding. As well as reducing weight, the component reduces the complexity of the axle, making it easier to install.

Another innovation is the lightweight McPherson suspension strut with integrated wheel carrier, which is made of GRP and weighs just half as much as conventional steel suspension struts. The concept is based on use in mini and micro cars under a ton in weight. An upside-down design for the cylinder tube compensates for high bending stress, and the strut provides all the characteristics of a modern damper. ZF is working on applying this technology to larger vehicles.

Summary

Glass and carbon-fiber reinforced plastics are increasingly being used in all areas of automotive manufacturing. Production times and costs are falling, and new technologies are developing stronger, more flexible products than ever before. The use of such plastics in suspension systems is expected to increase as volume production processes improve, and more complex parts can be made in mass numbers.

Innovations in suspension design, such as those demonstrated by Audi and Citroën, show that there are several ways in which development can progress. The use of lighter metals and plastics can provide engineers with greater freedom of design as they develop the next generation of suspension systems. However, this development must always be balanced against cost of production, increasing crash safety targets and overall integration with the powertrain - particularly with the anticipated advent of 48 Volt electrical systems.

- Interested in the latest developments in advanced suspension systems? Automotive IQ's Advanced Suspension Systems 2020 conference takes place from 21-23 April in Germany. Get all the details here.

Sources:

https://www.zf.com/corporate/en_de/magazine/magazin_artikel_viewpage_22131368.html