Volvo on safety of braking power feed: implications for electrical architecture

Add bookmarkAutomotive IQ interviewed Mr. Quintus Jalkler, System Architect brake system at Volvo Cars, with some insight into ways of mitigating single failure problem with 2 batteries system for separate power supply to callipers.

1. The are many redundant options imaginable for securing the braking within the electro-mechanical system. Why having 2 batteries?

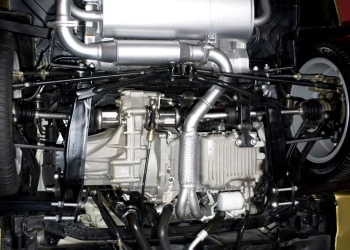

Because if one battery goes down you do not want to have a system that is unable to stop the car. Then you need to have a second power source to give the brakes the needed energy to stop the car. Then you can look more into the options like if we have 2 power nets instead of just 2 12v batteries then that can be a option instead of adding cost and weight for the extra 12v battery. Then you will need to have a good hand over between the 2 systems if one would go down. That is something that could be done in the ECU of the brake component to have both 12v and 48v power supply as an example.

2. How do you see the future of braking systems? Will the hydraulic system remain to some extent or will it be fully electric?

I think that there will be a future for hydraulic systems for small cheaper cars, but the bigger and premium cars will go to electrical calipers. Because if you don’t have a need for redundancy on the brake side due to autonomous drive or co2 benefits then its hard to compete with the cost of a standard brake booster HECU system.

3. Is the 48V really needed in future braking systems? Can the actuation power be kept low and hence remain satisfied with 12V?

I think that the brake system can survive with 12V if the motors of the electrical calipers have a low power consumption. Then you have a benefit with having dual power supply both from 12v and 48v.

If we see that we can use 48V in combination with 12 v then we can have dual power nets and there get a benefit for the system. But to get back to the question about 12V vs 48V i don’t see that we need to go to 48V for the future.

4. Please name 1 thing, that you see coming in packaging of electric braking systems?

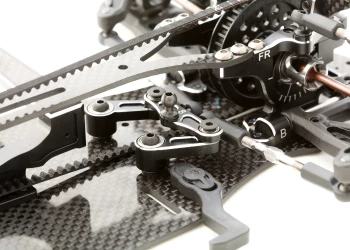

Smart packaging, how to design a caliper that is slim so it don’t take too much space to the wheel suspension.

And at the same time get a good looking caliper that don’t compromise function before “good looks”, because the cars today get bigger rims and then the caliper will go from just at hidden part to a design statement.

The electronics then need to be packaged in a way to not disturb the visual impression of the car and in the same way still be packaged so it will get away from the heat of the brake disc.

So the caliper will both be a design and a functional part in the coming cars.